Why training and through-life support adds real value to capability

Ewan MacDonald, Training Manager at EWS asks why it is that Original Equipment Manufacturers (OEMs) often sell equipment to a customer, but don’t or can’t always provide either formal or contextual training on the equipment after delivery? Over the years, he says he’s experienced this many times over, both in his military career and during his recent foray into industry. Although there are always fiscal implications on the provision of this type of training, the learning outcomes and opportunity to build a lasting customer relationship are well worth the investment.

As part of an integrated logistics plan, we broadly follow the UK’s Defence Lines of Development (DLoDs) concept at EWS. Wherever integrated logistics are provided, training is a fundamental part. In times of financial stress, it’s often that training is trimmed down to a minimum but in my experience that really can be a false economy.

OEMs need to win business and be competitive in their tenders so if training is not included as a specific requirement and/or amortised across the cost of the system then it’s natural for it to be ‘cost effective.’ However, I really do feel that it’s a missed opportunity for an OEM to allow systems to be fielded without a formal training package being delivered alongside it aimed at the specific user and their own unique concepts of operation and employment (CONOP/CONEMP). Many of the systems we support are mission critical and getting it wrong can genuinely impact on the safety implications for users’ lives and the subsequent success of the mission; let’s look at this in more detail.

Looking beyond delivery to through-life training and support

I understand that even on small contracts Bid Managers and capture teams need to win a competition, says Ewan. There are always debates regarding suitable spares packages, in-country support and of course training. I know from personal experience that significant time is spent trying to capture the sale, with considerable debate back and forth regarding consumables and accessories, arranging export, sorting out delivery schedules, and then if successful, shipping the systems. ‘Phew’, finally after all that, the job is done!

I understand that even on small contracts Bid Managers and capture teams need to win a competition, says Ewan. There are always debates regarding suitable spares packages, in-country support and of course training. I know from personal experience that significant time is spent trying to capture the sale, with considerable debate back and forth regarding consumables and accessories, arranging export, sorting out delivery schedules, and then if successful, shipping the systems. ‘Phew’, finally after all that, the job is done!

However, in his opinion it’s worth the OEM looking beyond the simple provision and fielding of the system. There is real value in providing great support, which as we all know, is one of the best business development tools; especially when dealing with the operational community.

Through life support technically and from the sustainment (and training) perspective does contribute to the generation of ongoing revenue so including a viable and affordable through-life training capability, fine-tuned to an organisation’s own learning continuum provides benefits for all concerned and maintains the ability of the system to be used to the very best effect.

Turning equipment into a capability

At the point of delivery, the customer is happy. They have just bought a sparkling new equipment with a life span of at least five years, before they even need to consider replacing the system. At this moment in time, they have the technology but it is not yet a capability.

A system only becomes a capability once it has been received by the end user and they have been trained on its full functionality and scope of use, allowing the user to make informed decisions on how best to use the equipment in the role it was purchased for. The aim is to push all systems to the fullest extent of their operating parameters.

But if a focussed learning and maintenance package hasn’t been included as part of the equipment delivery, what happens next?

Well, there’s always the option of turning to the user manual and trying to self-teach the system but we have all been subjected to manuals that aren’t geared towards the operational user. That’s also assuming that the user has sufficient understanding of technical English to decipher and follow the manual and that it was supplied in their first language. In practice, with the manual in hand, the user might discover perhaps only around 50% of the true capability of the equipment through his/her own trial, effort and endeavour.

Often in our world, equipment is particularly complex and there is the danger that the end user won’t ever really understand how to gain the maximum use from the equipment, and in some cases I’ve seen the equipment end up on a shelf and remain there, gathering dust.

Then the problems for the OEM start with the customer complaining that the equipment is not fit for purpose and doesn’t do what the requirement called out. However, in reality, often it’s the lack of training of the operator and their in-depth knowledge of the equipment that’s actually the real issue. We see a tendency for the blame to be placed directly at the hands of the OEM and not the lack of focussed training, irrespective of the real reasons.

Having seen these training shortfalls on so many occasions, it is worth discussing with the OEMs the benefits of through-life training and whether it is viable to incur some of the costs internally to become the provider of choice and ongoing supplier of specialist capability.

Even Shipley asks us if we can remove the current incumbent? The best incumbent will always be the one who goes the extra mile to ensure the success of the mission and the safety of the user. Shipley is correct, a really good supplier is hard to remove!

Building a lifelong relationship with the customer

A good training program with good instructors develops great relationships, friendships and ultimately, partnerships. I have friends all over the world who I have trained and trained with and they still come back to me now for a chat, advice and for further training.

With a satisfied customer and well-trained operators, you can then add even more value to the relationship through periodic refresher training or even, Train the Trainer (T3) programmes to further increase their capabilities. In the ideal world, these costs can be built into your contracts at the negotiating stage or at least added on as options.

If we get the relationship and training right this is a win-win situation for everyone. The customer is happy with their equipment purchase, the user is confident with the equipment, and capability is increased through a delivered programme of continuous training; inevitably repeat business comes your way.

And so the cycle repeats itself.

But what if you don’t have readily available trainers?

Ewan finishes: This is where EWS can work with you to manage these potential training gaps with you, bringing all the bonusses identified previously, thus helping increase business wins and revenue opportunities, and give you an edge over your competitors.

Ewan finishes: This is where EWS can work with you to manage these potential training gaps with you, bringing all the bonusses identified previously, thus helping increase business wins and revenue opportunities, and give you an edge over your competitors.

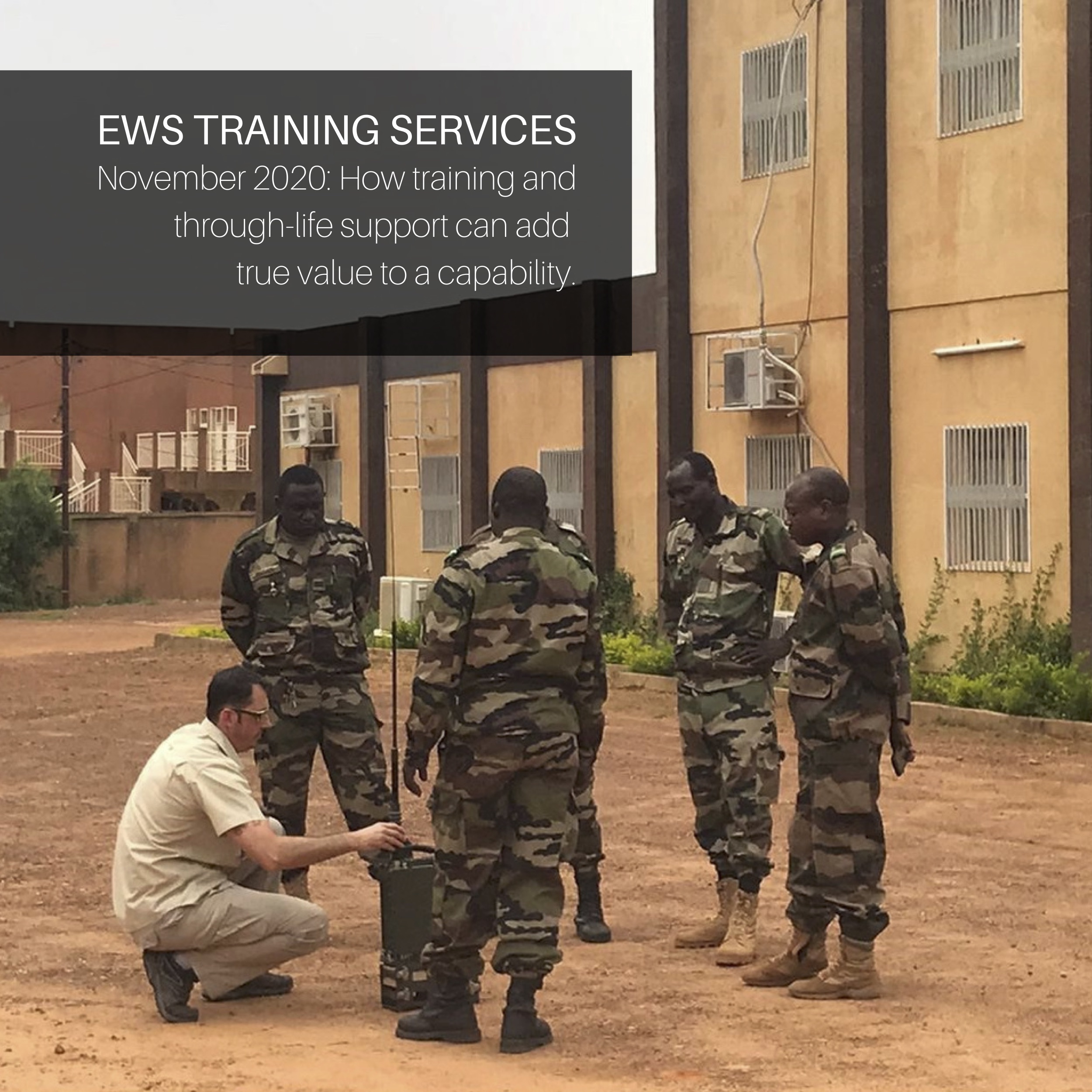

Our training teams have the ability, experience and support to operate in hostile or challenging environments. We understand the difficulties that large companies often have trying to get trainers into a country that, let’s say, challenges HR policy. Efficiencies of training mean that often, the most cost effective and viable training is delivered via a mobile training team (MTT) at the customer’s location. Our team excel at providing MTTs globally in support of specialist technology and have the expertise and flexibility to work in these often-challenging environments.

Let EWS ease your training burden – A message to OEMs

As a small, agile, equipment agnostic company with a good relationship with all OEMs, EWS would like to help in easing the training burden for you, representing your product line professionally and at the places where it’s most needed.

All our highly qualified instructors have experience in training overseas, in hostile environments, and as a result can also bring added operational context and operational experience to our training programmes and the OEM’s system.

This added value will ensure both the customer and user fully understand the functionality of the system in the operational context and gets great value for money and the best from the product.

As we employ operationally experienced trainers, they provide real time feedback in the form of a written report on how the equipment is fielded, any issues arising with the equipment and, if required, can make suggestions on changes that could further enhance the capability. This feedback can be of real value when it comes to the development of future systems.

Finally, congratulations! Now you have now turned your equipment sale into a capability and gained a competitive advantage that could reap significant repeating financial rewards for many years to come.

Want to know more about training and through-life support from EWS?

The next steps are easy, just contact Ewan MacDonald at EWS for a no-obligation chat about how his team of experienced trainers can help you.

Contact us and let us turn your equipment into a capability today.