Proving the value of Field Service Representatives – a Case Study

Here at EWS, we like to take customers purchasing an electronic countermeasures (ECM) equipment on a journey. This is not a physical journey but a virtual one where we introduce where relevant, each of our business streams: Intelligence, Consultancy, Training and Engineering Services, adopting a ‘cradle to grave’ approach and walking the customer through the entire procurement process to thoroughly understand the issues and challenges to be solved.

For some, Field Service Representatives (FSRs) can be a bone of contention when it comes to a contract. Many see their cost as prohibitive and on paper it can be difficult to see the added value that engineers bring to a project. Initially, the costs involved in deploying FSRs to mentor, train, retrain, provide real time advice, liaise with in-country entities, and provide integrated logistic support (ILS), can look like an expensive commodity.

So, why are you telling us all this “again” I hear you ask? Well, we’d like to share with you a recent example which we feel helps to explain the importance of FSRs and the intrinsic value they really can add across the term of a contract.

Understanding the added value of Field Service Representatives

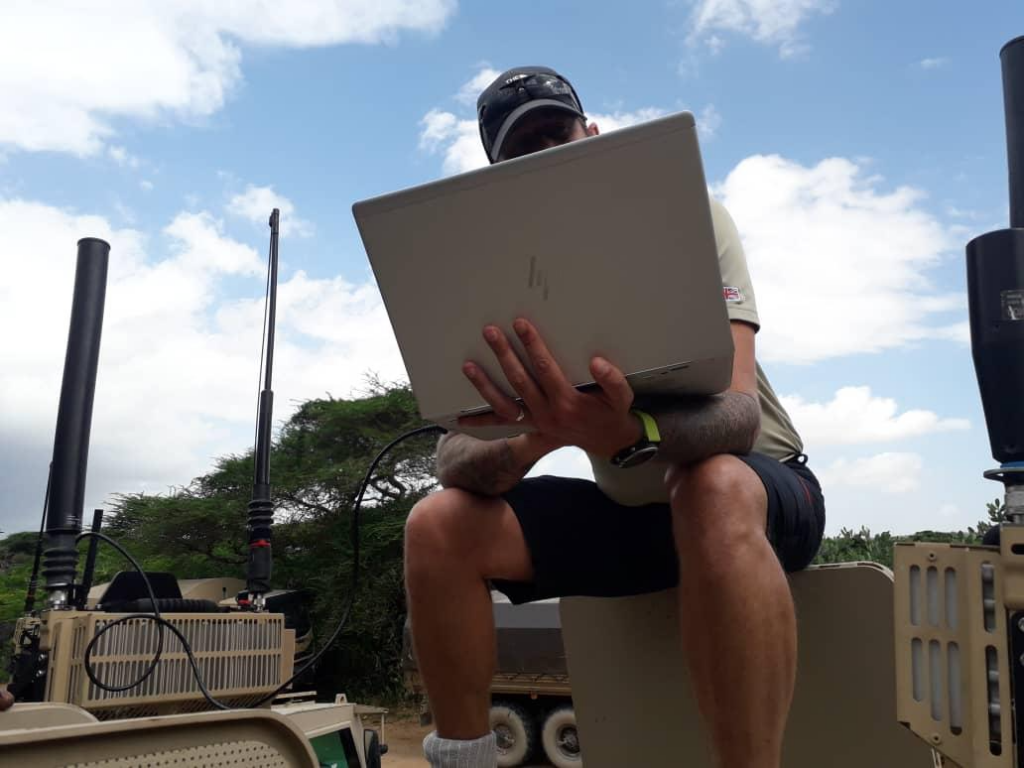

In this particular Case Study, our Field Service Representatives (FSRs) were embedded in-country to deliver a long-term contract in North Africa.

In this particular Case Study, our Field Service Representatives (FSRs) were embedded in-country to deliver a long-term contract in North Africa.

The EWS FSRs were providing ILS, training and mentoring to an African Union mission supporting an original equipment manufacturers (OEM) equipment through a defence contract.

However, as the operation progressed and as can be expected, it became apparent to the FSRs that the Radio Controlled Improvised Explosive Device (RCIED) threat had changed significantly along with the tactics, techniques and procedures (TTP) employed by the insurgent grouping.

However, as the operation progressed and as can be expected, it became apparent to the FSRs that the Radio Controlled Improvised Explosive Device (RCIED) threat had changed significantly along with the tactics, techniques and procedures (TTP) employed by the insurgent grouping.

This change in threat was not common knowledge as most devices in country were not being recovered, so no technical exploitation was being conducted on them. This change in the threat was also not widely reflected in open-source reporting from in country.

Because of their vast amount of operational experience, the EWS FSRs recognised that because the threat had changed the equipment would no longer be offering the correct level of protection to personnel. They realised that they needed to speak with the intelligence branch in country and very quickly established that the threat and tactics had indeed changed.

Developing the Mission Fill to counter the threat

The in-country FSRs flagged this change in threat back to EWS HQ in the UK. EWS then contacted their close partner to develop a Mission Fill (MF) to counter the new threat. Our partner started work on the MF and developed an initial fill which was subjected to a verification and validation (V&V) process.

It was initially found that the MF results achieved in the UK were not being replicated in country via a representative system and MF. So, the MF was taken back to the drawing board and a baseline for testing was established between our partner and the in-country FSRs. Adjustments were made to the MF and again, the results from theatre did not match those achieved in the UK. It was decided to get all involved parties on a call to discuss what the likely problem may be.

It was initially found that the MF results achieved in the UK were not being replicated in country via a representative system and MF. So, the MF was taken back to the drawing board and a baseline for testing was established between our partner and the in-country FSRs. Adjustments were made to the MF and again, the results from theatre did not match those achieved in the UK. It was decided to get all involved parties on a call to discuss what the likely problem may be.

During the call, it was then established that the TTPs employed by the insurgent grouping had changed significantly. The TTPs employed required a reworking of the MF to enhance its performance against this specific threat. As is well known, Electronic Countermeasures (ECM) equipment is not a silver bullet and, as the insurgent changes his tactics when deploying a device, friendly tactics may also have to change to counter the threat, alongside the enhancement to the MF. When prolific threats are covered by ECM MF, the insurgents will move to other parts of the spectrum to try and initiate RCIEDs. As far as MF is concerned, we need to ensure the current prolific threat is countered but also to make sure all other viable threats are covered.

The following days involved direct liaison between the FSRs and our partner. This liaison allowed the technician to adjust the MF parameters to enhance the MF so it met the requirements of this particular theatre.

The following days involved direct liaison between the FSRs and our partner. This liaison allowed the technician to adjust the MF parameters to enhance the MF so it met the requirements of this particular theatre.

This liaison continued over a weekend until the best results possible were achieved. Within the space of a week, a tried and tested, verified MF was developed and delivered to theatre, followed up by an independent technical report detailing the processes involved in the MF development and the findings of the trials.

Time for reflection

When the dust had settled and the waveforms and associated files had been passed to theatre via an export license, the team had time to reflect. Personally, two phrases stand out and strike a chord as to why we at EWS employ a ‘cradle to grave’ approach in walking the customer through the entire ECM procurement process.

The first phrase was received from our partner’s technician who developed the MF. He commented “I have never seen or created a waveform quite like it. The key was fully digesting and understanding your description of the threat. It’s not often we get direct feedback like that.” Without the experienced FSRs in-country recognising the changes to the threat, the equipment would never have fully fulfilled its purpose of saving lives.

The second phrase was received from the EWS in-country manager John Cordery, who was instrumental in providing the up-to-date intelligence for our partner to build the MF and managing his in-country team to carry out structured V&V of the new wave forms. John commented “Thank you all for your hard work and diligence, you will have made a difference out here, I am sure.”

So, to answer your question, “Why do I need to pay all that money for an FSR to support my equipment?”. This is a real-world recent example of why FSRs are worth every penny compared to the cost of a life!

- Extensive operational experience meant the EWS FSRs recognised that the threat had changed.

- Critical intelligence was then gained from relationships in country, clearly describing the new threat.

- This was backed up with a phenomenal technical support team in the UK, partnering to develop the MF.

- Direct liaison between FSRs and the technician to ensure the MF was fit for purpose.

Our Field Service Representatives help to save lives in quick time in foreign countries. That’s why we believe they are worth it and at EWS we will continue to recommend their support of OEM equipment on delivering contracts in-country.

Further reading

EWS has written two white papers on the subject of MF development and employing FSRs to provide ILS to OEM equipment. If you are interested in receiving these papers, then please contact our Head of Operations, Paul Crawley at paul.crawley@solutions-ew.com